For decades, there have been fears in the manufacturing industry that robotics might be the one thing that emerges as a job threat for millions of blue-collar workers.

You can hardly find a science fiction novel, movie, or television series set in the future that didn't casually introduce robotics as a "normal" thing that smoothly blended into society.

It's everywhere.

Everybody knows R2-D2 and C-3PO in the "Star Wars" movies, which debuted in the 1970s, as a jolly Abbot and Costello-like duo.

Further back there was, of course, HAL-9000 from the 1968 novel "2001: A Space Odyssey." "I'm sorry, Dave, I'm afraid I can't do that."

More recently, the television series "Westworld," based on a movie of the same name, introduced a new generation of helpful humanoids that become sentient and revolt.

Yes, robots and robotics have been playfully toying with our minds - are they helpful or will they all become "Terminator?" - for so many decades.

However, here we are in 2024, ready to hand over our society to robots as long as they make things easier on ourselves as Boston Dynamics robots jump for joy.

Still, it's not all bad, so far, is it? Below are four use cases for robots that have already had a positive effect on one of our oldest industries, manufacturing.

Robots in manufacturing - Assembly Line Tasks: Repetition and precision is a robot's game, right? Just program them right, hit "execute" and, there you go. Millions of bolts fastened, windows produced and widgets all placed in uniform fashion.

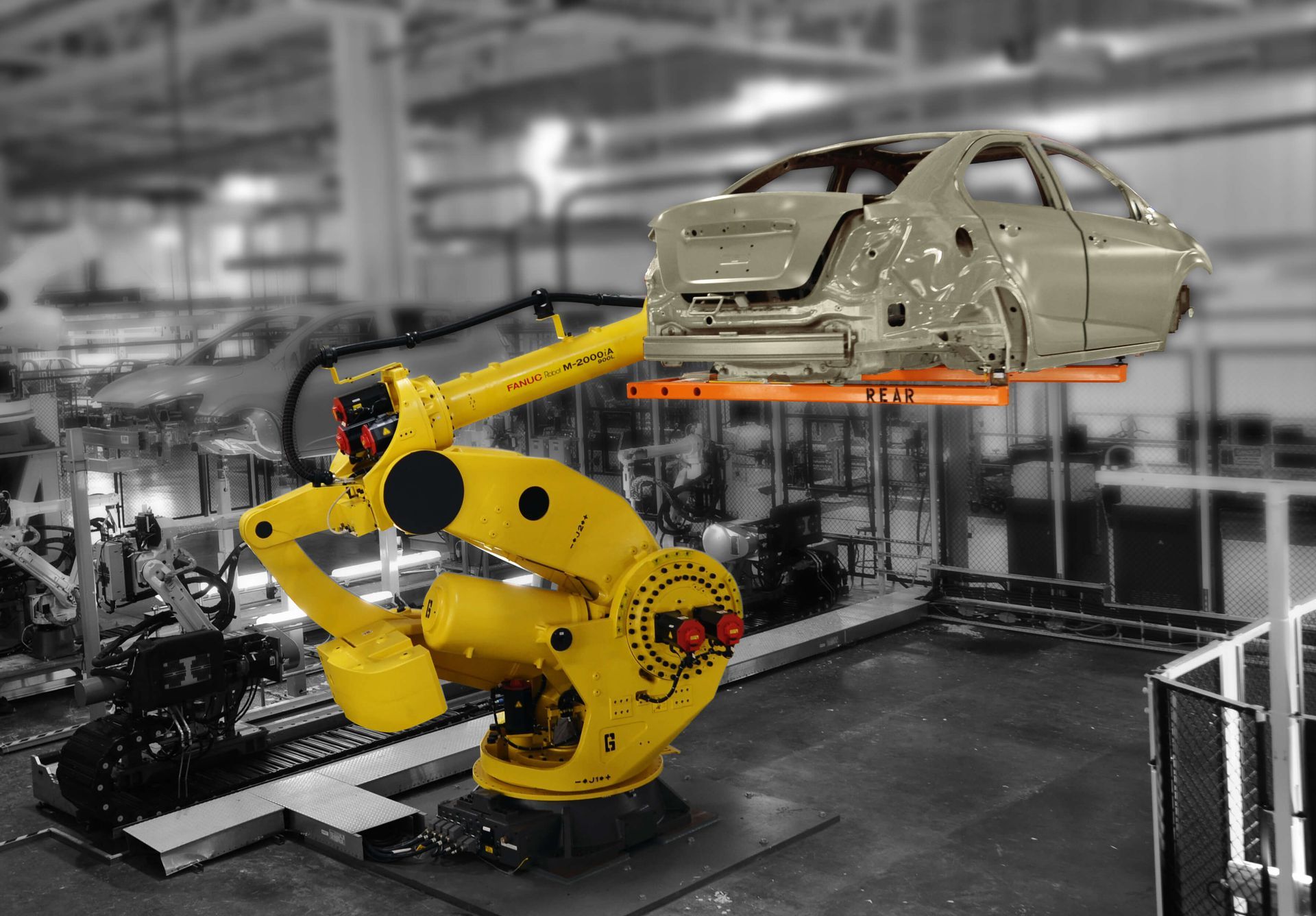

That's right, robots excel at repetitive and precise tasks on assembly lines. They can weld car parts, assemble electronics, and perform other tasks with high accuracy and speed, improving production efficiency.

Robots in manufacturing - Material Handling: Robots can handle heavy or bulky materials, reducing the risk of injury to human workers. They can be used for tasks like loading and unloading pallets, moving materials between workstations, and feeding machines.

This is an area where humans against robots just really have to accept that these processes are far better than when we had to load them up on pallets and move them with a pallet jack.

Robots in manufacturing - Quality Control: This one is likely something that will become a common use case as internal systems become more accurate. Robots equipped with vision systems can inspect products for defects with greater accuracy and consistency than human inspectors.

This helps to ensure product quality and reduce waste. Again: although this has been around for decades, as people develop stronger optics systems, they will become even better moving forward.

Robots in manufacturing - Painting and Finishing: One thing you'll notice on this list is that the tasks tend to take advantage of a robot's repeatability. In this case, robots can apply paint and other coatings to products with a high degree of precision and consistency.

This improves the quality of the finished product and reduces the amount of paint or other materials used.